QAWT has developed an extensive range of procedures and techniques for weld inlay and weld overlay cladding applications for the Offshore, Petrochemical and Power Generation industries.

They are the result of over 35 years’ experience of supplying weld overlay cladding services using corrosion resistant alloys (CRAs).

- Our Fronius cladding systems with column and boom, cross-slide system, rotary table and digital welding source allows us maximum flexibility to meet our clients’ specific applications.

- Real time monitoring of all welding parameters.

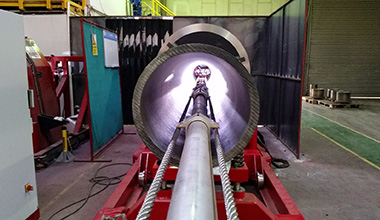

- Heavy and complex work pieces can be handled by our ETR (Endless Torch Rotation) System which allows welding of work pieces with different bore angles, delivering high throughput and consistent results.

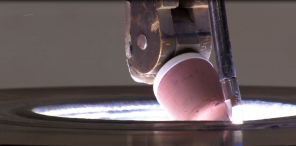

- Pipe cladding is carried out on our twin-wire TIG rigs enabling us to inlay bores from 40mm diameter and up to 12 metres long.

- Submerged-arc welding is available to complement QAWT’s full range of inlay and overlay capabilities.

- We have developed a full range of approved welding procedures including welding deposits with Stainless Steel, Inconel 625, Incoloy 825, Aluminium/Bronzes, Monel and Stellite on base materials ranging from CMn Steels through to AISI 4130, CrMo’s, F6NM and Duplex Stainless Steel.

- Weld inlays and weld overlays can be carried out on components for final machining by customers or within our extensive machining facility.

- QAWT is approved by ASME for the weld overlay of clad components, holding both Div1 U and Div2 U2 STAMPS.

- NDT, post weld heat treatment and final certification are available to meet customer requirements and specifications.

Our Sectors

Latest News

10th Feb 2020 - QA Weld Tech celebrates 40 years

It’s our Birthday! 40 years ago our MD, Charlie Tighe, set up QA Weld Tech on the then new Riverside Park Ind. Est. Middlesbrough and we’re still going strong. Thanks to past and present employees for all your hard work…