With an engineering team, led by our Technical Director and European Welding Engineer, Richard Knowles, we are able work with clients to solve the complex problems they encounter. Advice on base material selection, weld overlay suitability, and heat treatment processes to achieve the desired results is available.

Project: Inlay of ‘Y’ Pieces using Alloy 625

Base material: ASTM A707 (modified L5)

Weld overlay material: Inconel 625 (Alloy 625)

Whilst we could demonstrate PQR inlay experience on A707 material, bore to bore programming of the TIG cladding machines and operator expertise, we could not demonstrate all of these parameters on a ‘Y’ piece configuration and decided to undertake a development project to verify our capability.

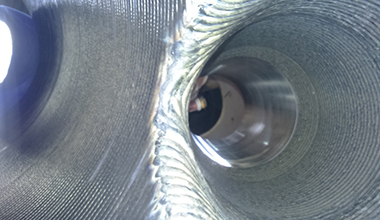

- The main challenge in inlaying a ‘Y’ Piece configuration is the angled intersection of the branch bore to the main bore.

- The Inconel cladding of the main bore could easily be undertaken with existing programmes on a PA 9000 Fronius hot wire TIG cladding machine.

- Similarly, the Inconel cladding of the plain bore of the branch could easily be undertaken with existing programmes on a Fronius ETR hot wire TIG cladding machine.

- The challenge was the angled intersection of these bores and in particular the ‘heel’ and ‘toe’ edges, especially as the ‘toe’ had a feather edge and excessive dilution which could result in undesirable metallurgical micro-structures in service.

By making trial mock up test pieces we were able to develop welding procedures and parameters that could then be applied to full scale production mock up. Once we had proved that the PQRs and welding techniques developed on the mock up pieces gave the required chemical analysis, micro structures and hardness structures demanded by the project we were able to move onto successful production and delivery of the ‘Y’ Pieces.

Our Sectors

Latest News

10th Feb 2020 - QA Weld Tech celebrates 40 years

It’s our Birthday! 40 years ago our MD, Charlie Tighe, set up QA Weld Tech on the then new Riverside Park Ind. Est. Middlesbrough and we’re still going strong. Thanks to past and present employees for all your hard work…