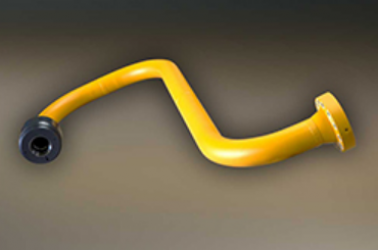

As a leading supplier of flowspools to the offshore oil industry QAWT combines a wide experience of the industry’s requirements to provide a complete project management service embracing all aspects of production, testing, certification and documentation.

- Flowspool manufacture is carried out by dedicated Induction Bending machines with capacity induction coils used for bending within 2’ – 8”, 2” – 18” and 10” – 30”.

- All flowspools are jig built to close industry tolerances. Over 650 approved welding procedures are also available for an extensive range of materials, including Super Duplex & Alloy 625.

- Project specific weld procedures and First Article testing available.

- QAWT also has extensive bore and RTJ inlay expertise using computer controlled Hot Wire TIG cladding machines to produce fully clad carbon steel production systems.

- CMM dimensional and CSWIP visual inspection.

- NDT, post weld heat treatment and hydrostatic pressure testing is available to meet customer specification and API codes.

- Spool coating and insulation.

- Protective packing to destination.

Our Sectors

Latest News

10th Feb 2020 - QA Weld Tech celebrates 40 years

It’s our Birthday! 40 years ago our MD, Charlie Tighe, set up QA Weld Tech on the then new Riverside Park Ind. Est. Middlesbrough and we’re still going strong. Thanks to past and present employees for all your hard work…