With our flexible production facility and dedicated Project Managers we can set up to deliver project equipment to client specific schedules. Recent examples include:

- Over 100 off 10” & 8” Pullhead assemblies for the BP West of Shetland Development with a work scope that included the manufacture of fully clad multi-bore hubs and phased delivery over 12 months.

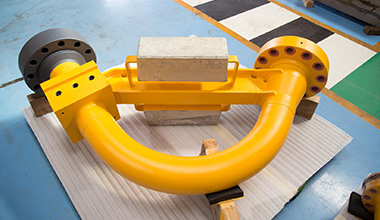

- 80 off Goosenecks for Petrobras in Brazil; a full turnkey project that included pressure testing, coating, sacrificial anode installation, and all ancillaries, packed and delivered to client.

- Pipeline End Manifold (PLEM) Systems including 24” Header CHCC, 16” Branch CVC-S and 10” Branch CVCs, fully clad with Alloy 625.

Our Sectors

Latest News

10th Feb 2020 - QA Weld Tech celebrates 40 years

It’s our Birthday! 40 years ago our MD, Charlie Tighe, set up QA Weld Tech on the then new Riverside Park Ind. Est. Middlesbrough and we’re still going strong. Thanks to past and present employees for all your hard work…